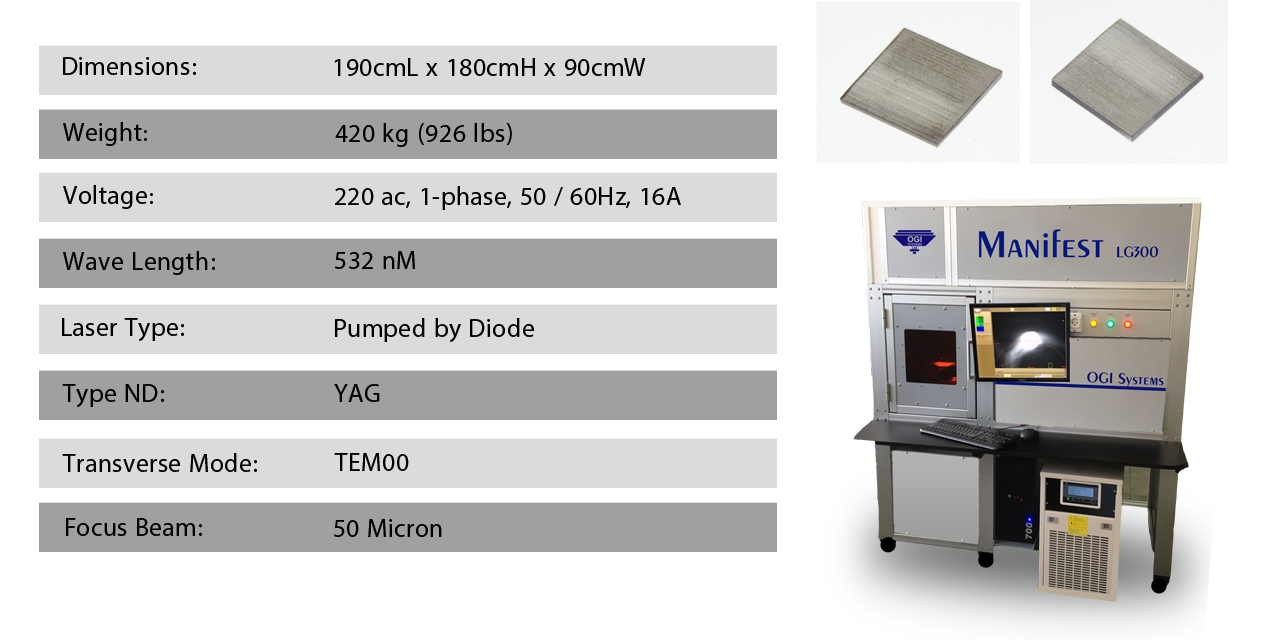

Manifest

CVD, HPHT Laser Sawing

The Manifest Green Laser of OGI Systems excellent for CVD & HPHT grower factories.

Can remove all CVD poly-crystal with any kind of shape like square, round or any other user desire .

Can cut thin slice for re-grow the CVD again or remove the HPHT seed.

Adapted to cut a large amount of stones a day.

can add 5X axis module to able to cut round coning stone.

OGI Manifest laser excellent for CVD and HPHT.

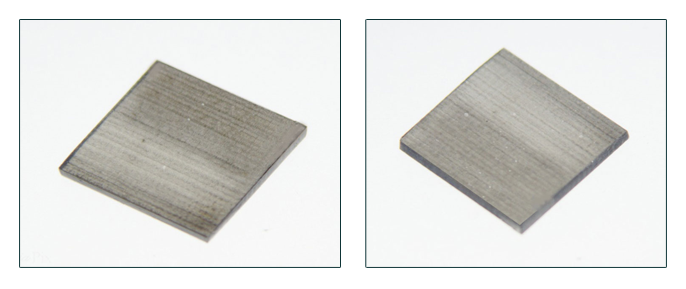

Minimal weight loss and low risk of breakage

Fast cutting time and user friendly processing

Fast cutting time and user friendly processing

No blackening, no opening, no double sawing needed

CVD coring and slicing in mass production

Special CVD software

Smooth cutting surfaces and sharp edges

Very thin beam resulting in perfectly parallel kerfs (no V-shape)

Virtually no heat impact thanks to the strong air cooling capability

Excellent to remove the CVD seed and HPHT iron seed

Build-in vacuum cleaner

Almost zero post treatment required

Attractive price

5 Axis Manifest machine also has an option to do:

Fancy and Round bruting, coning, faceting

Coring and slice in one time (no need to glue again)

Use of ultra-hard materials is growing in various industries and many manufacturers face the challenging need to increase their capability of manufacturing and cutting of these materials.

CVD Polycrystal

Lab-grown diamonds are generally produced with chemical vapor deposition (CVD) or high pressure high temperature (HPHT) method material for industrial applications.

The Manifest laser assists in optimizing the production from each single-crystal diamond.

Manifest laser-cutting produces perfect coring and slicing from every diamond seed.