SOLICO DIAMOND

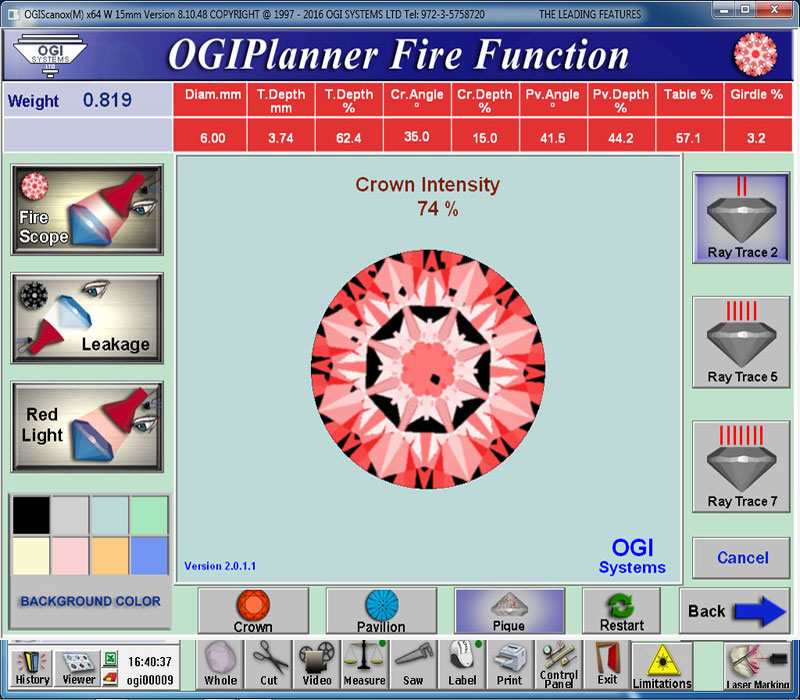

3D Laser Modeling for Diamond

3D Laser Modeling for Diamond

With OGI Solico - The Future Is Now

Low man power - Maximum profit

Low man power - Maximum profit

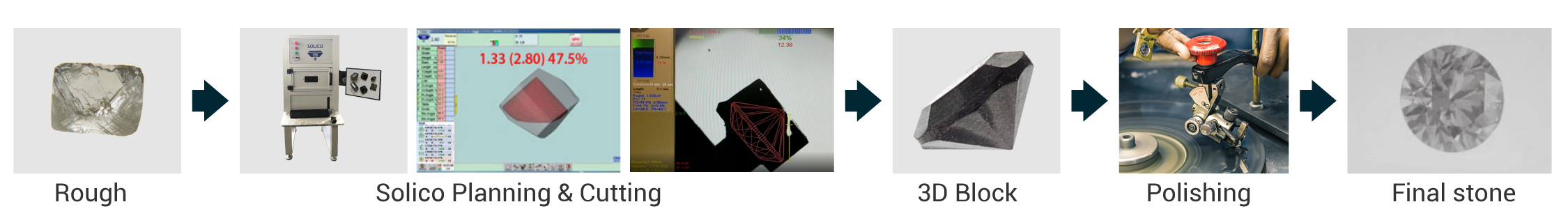

3D-modelling of any diamond shape using fiber laser to achieve a highly accurate result with minimal time and material loss.

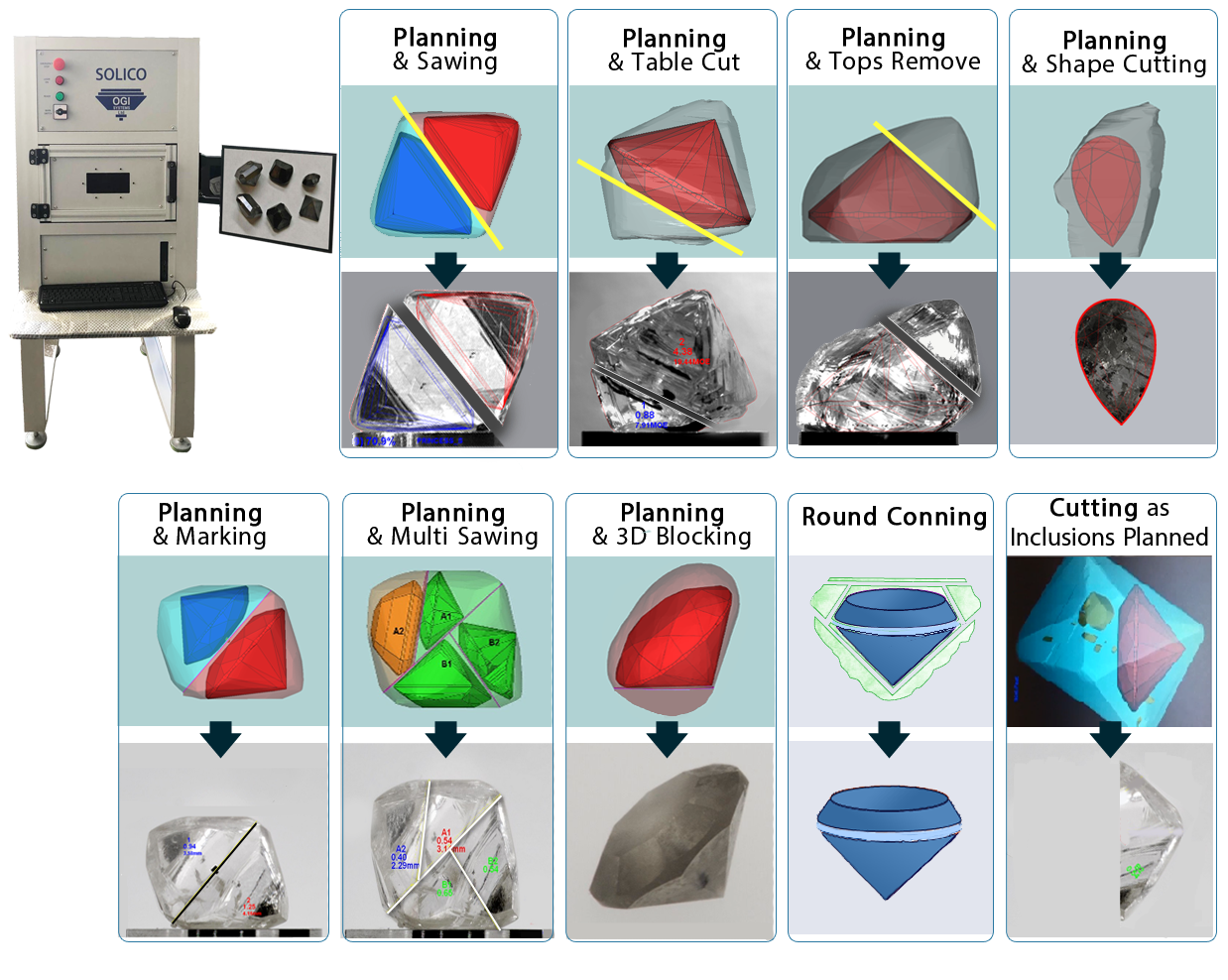

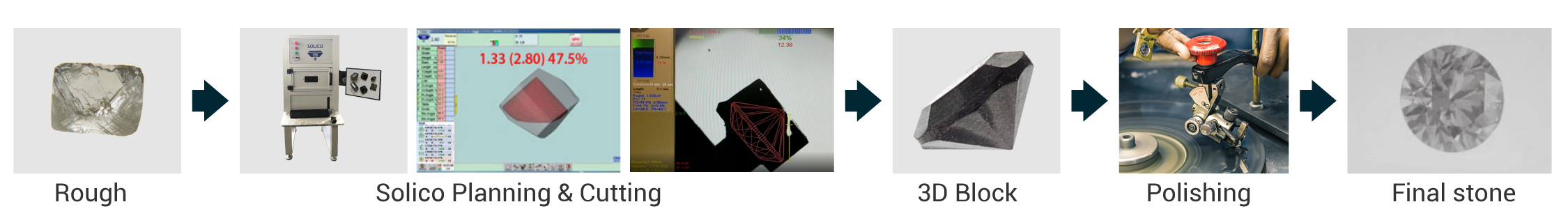

SOLICO is an acronym for "Scanner, Optimizer and Laser Integrated Compact OGI" and it is a mean of combining the laser sawing / cutting process and a 3D mapping apparatus as a single unit. The sequence of actions when using SOLICO can be deduced from its name: measuring (scanner), optimizing the yield (optimizer) and simulating and executing process (laser).

SOLICO has 5 Axis ( X,Y,Z and 2 rotations) , a measuring device to create 3D mapping of rough stone (Scanner) and allocate the best polish shape plan (Optimizer) and executing 3D process (laser).

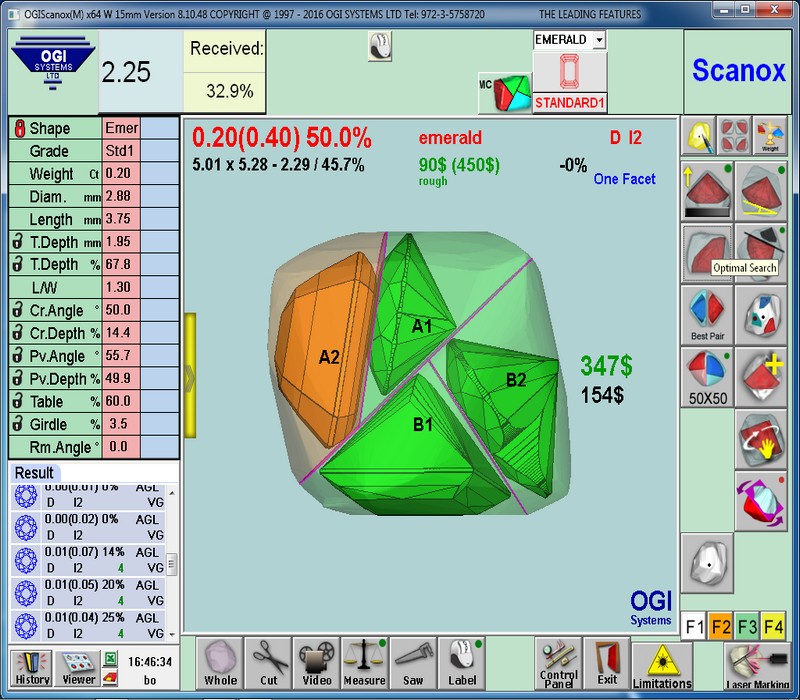

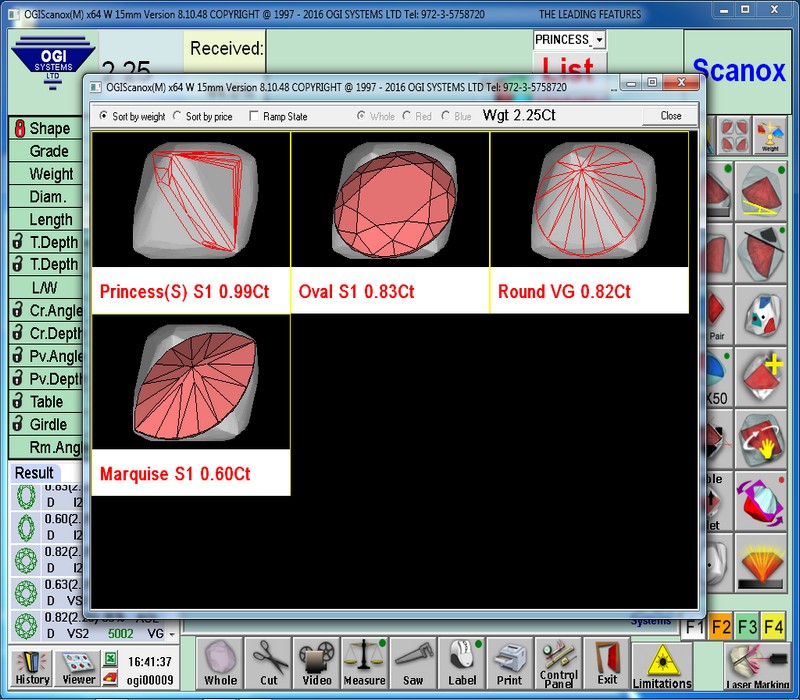

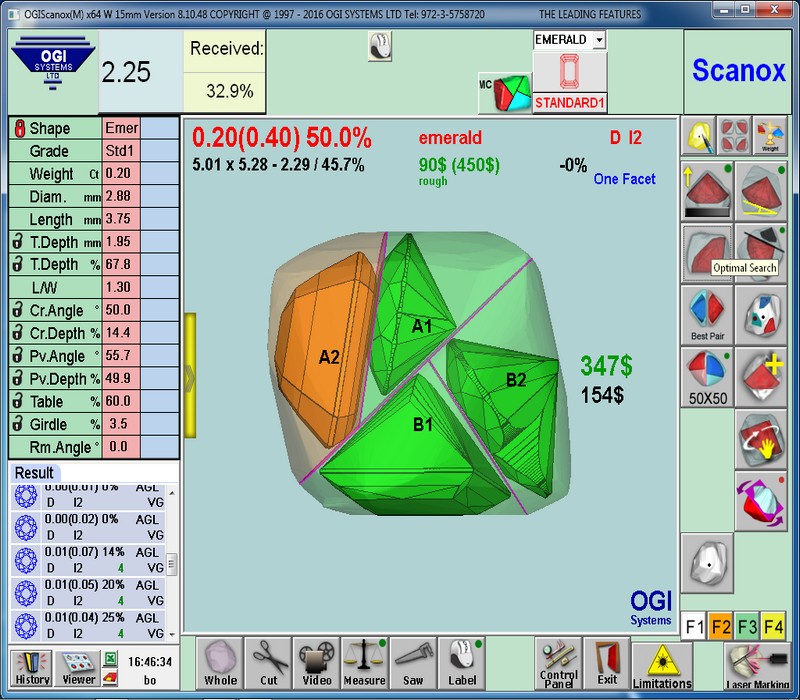

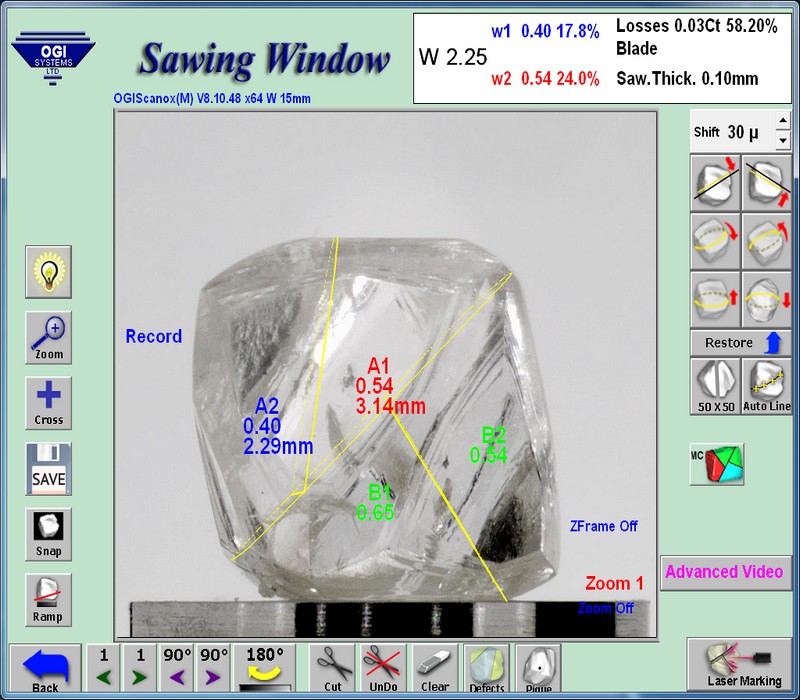

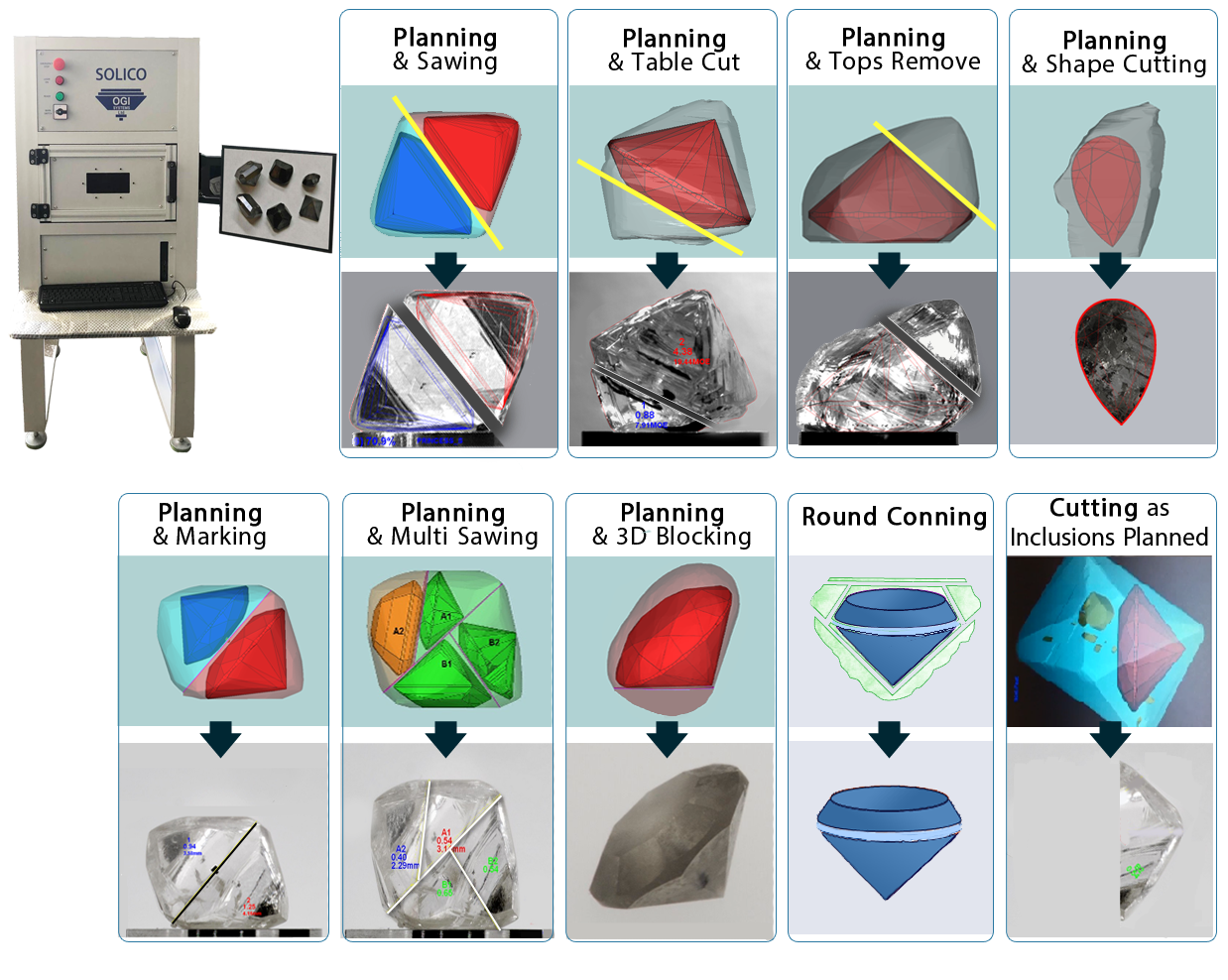

SOLICO, integrated with OGI Rough software, can allow you to cut rough stones at the middle or to get the best 50/50 pair rough stones or just table cut to make one single polish stone according to user's price list to get best value. SOLICO can cut any facets, table cutting, blocking, bruting and create any 3D model shape.

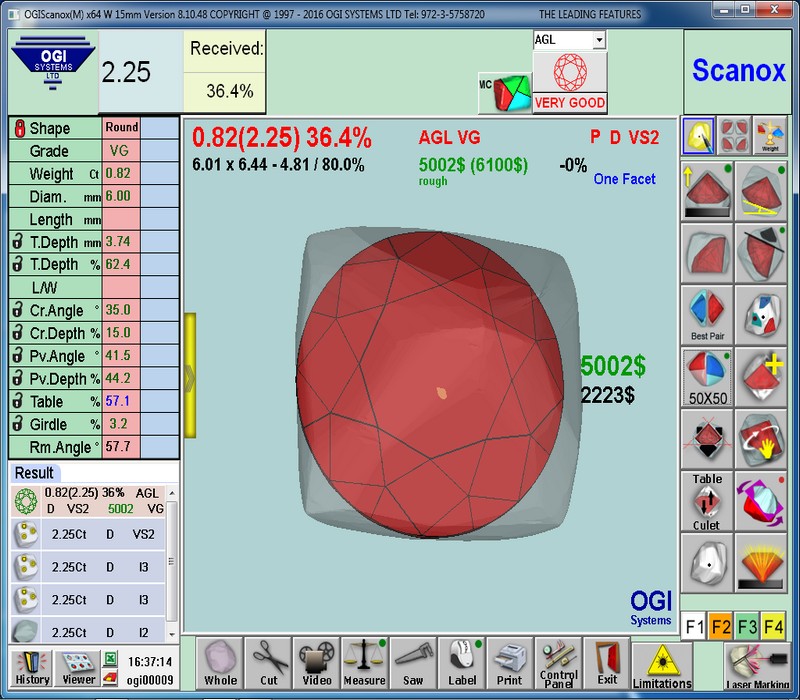

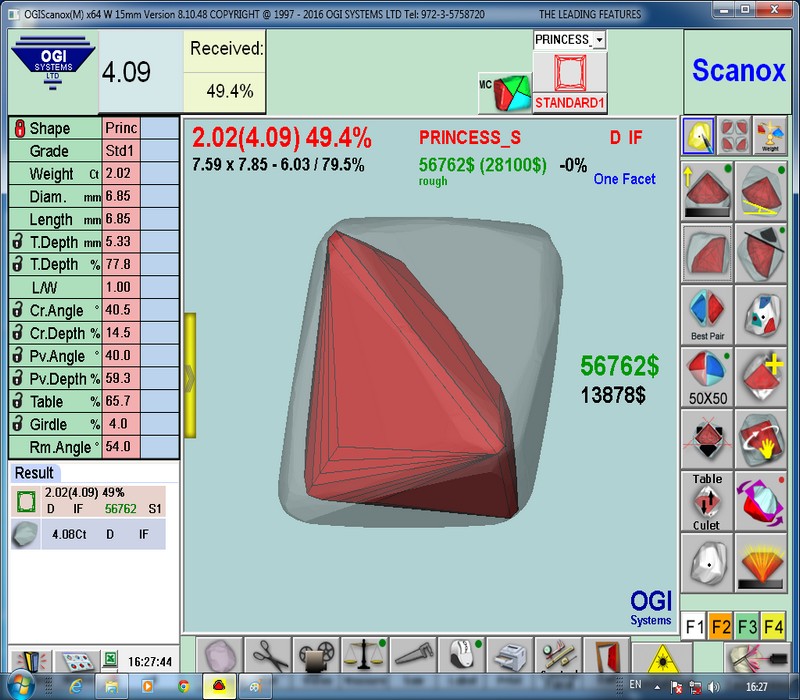

SOLICO is a more advanced compact laser system than Scanox Marking machine that ables you to cut / saw the stone. Think what you can do with a Scanox marking device and just replace the laser marking with a laser cutting maintaining all the other functions of Scanox marker which is SOLICO.

SOLICO is an acronym for "Scanner, Optimizer and Laser Integrated Compact OGI" and it is a mean of combining the laser sawing / cutting process and a 3D mapping apparatus as a single unit. The sequence of actions when using SOLICO can be deduced from its name: measuring (scanner), optimizing the yield (optimizer) and simulating and executing process (laser).

SOLICO has 5 Axis ( X,Y,Z and 2 rotations) , a measuring device to create 3D mapping of rough stone (Scanner) and allocate the best polish shape plan (Optimizer) and executing 3D process (laser).

SOLICO, integrated with OGI Rough software, can allow you to cut rough stones at the middle or to get the best 50/50 pair rough stones or just table cut to make one single polish stone according to user's price list to get best value. SOLICO can cut any facets, table cutting, blocking, bruting and create any 3D model shape.

SOLICO is a more advanced compact laser system than Scanox Marking machine that ables you to cut / saw the stone. Think what you can do with a Scanox marking device and just replace the laser marking with a laser cutting maintaining all the other functions of Scanox marker which is SOLICO.

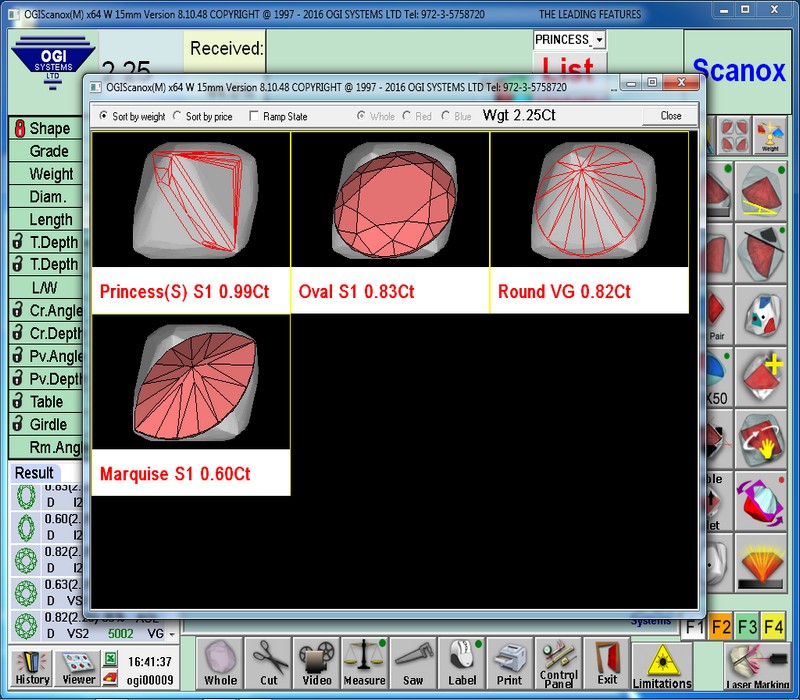

Solico results (Round, Oval, Asher, Emerald, Radiant, Princess, Cushion, Heart and Marquise )

Solico results (Round, Oval, Asher, Emerald, Radiant, Princess, Cushion, Heart and Marquise )and can do any customize shape.

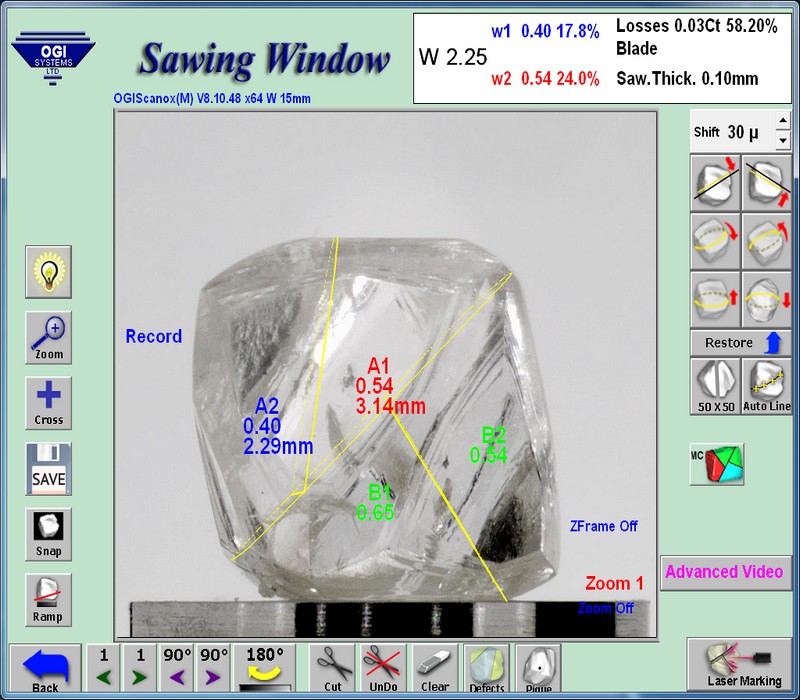

Solico 3D cutting

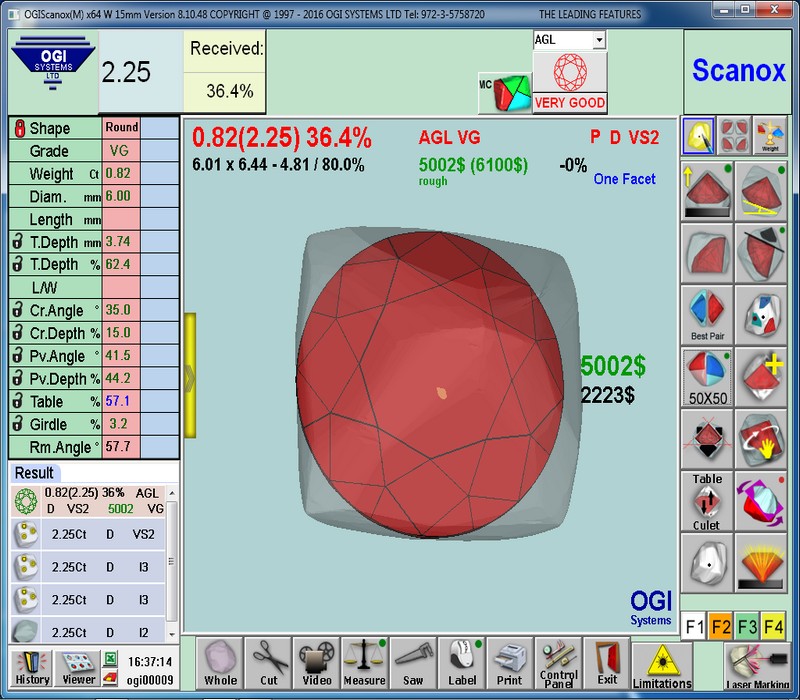

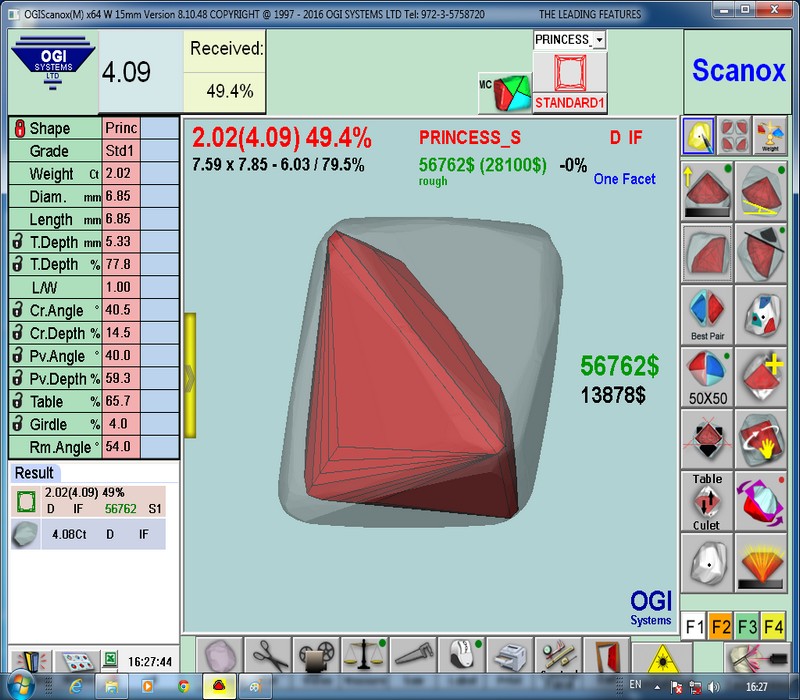

Solico planning

13mm Diameter size 9.67 Carat

WHY SOLICO

Melee Stones

10 points average stones

10 points average stones

"Tops" remain saving

"Tops" remain saving

Planning Software Embedded

|

Split

|

Clean Stone

|

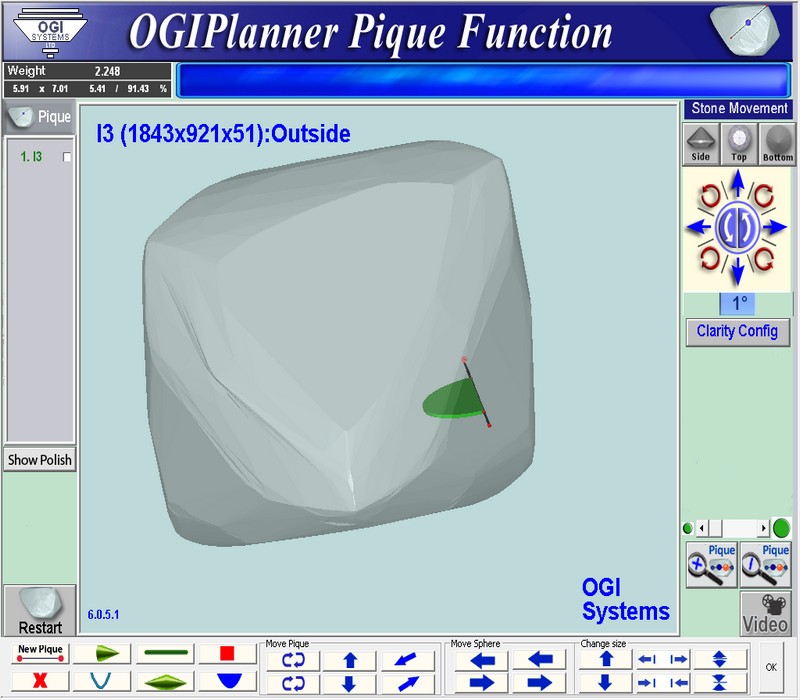

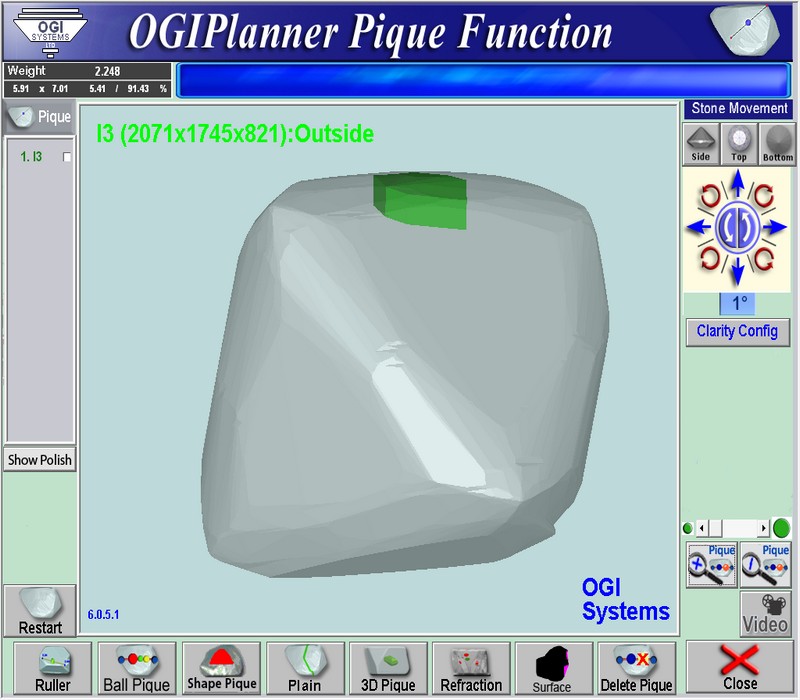

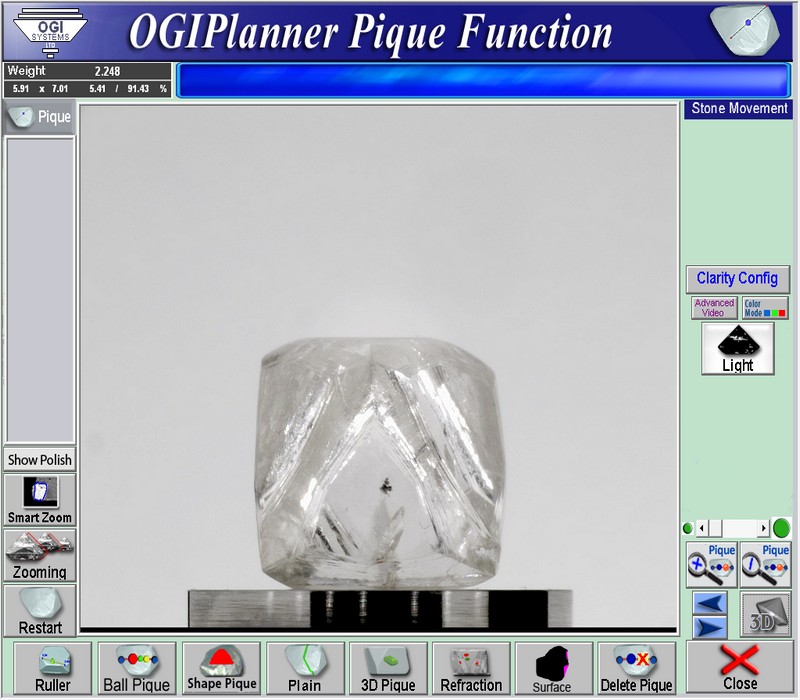

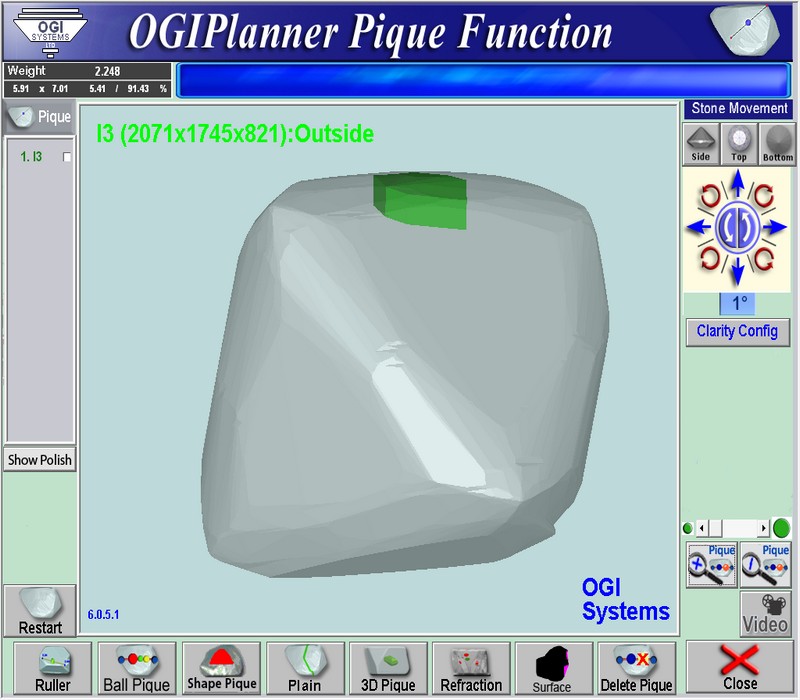

Fire Pique

|

|

Gletz

|

Hole

|

Multi-Plan

|

|

Multi-Shape

|

Multi-Saw

|

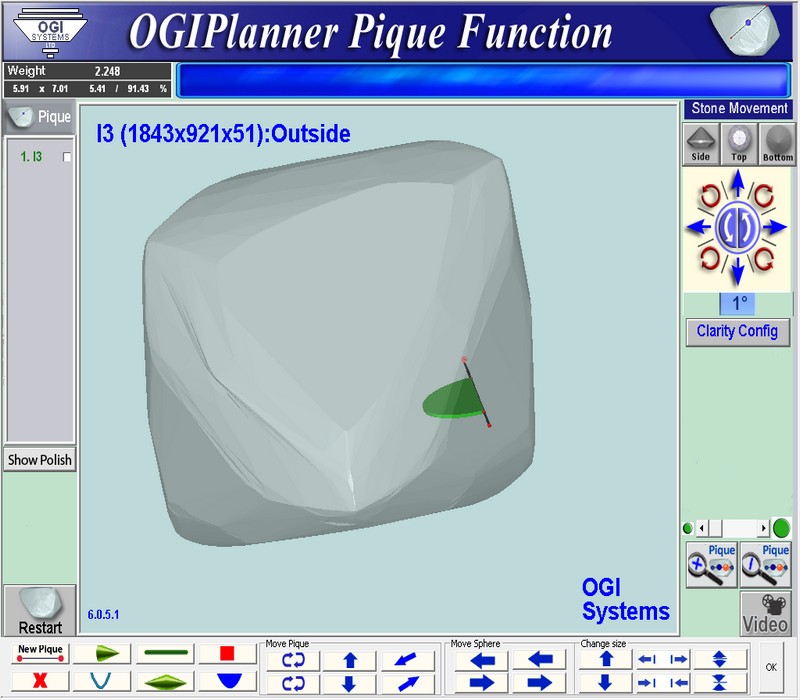

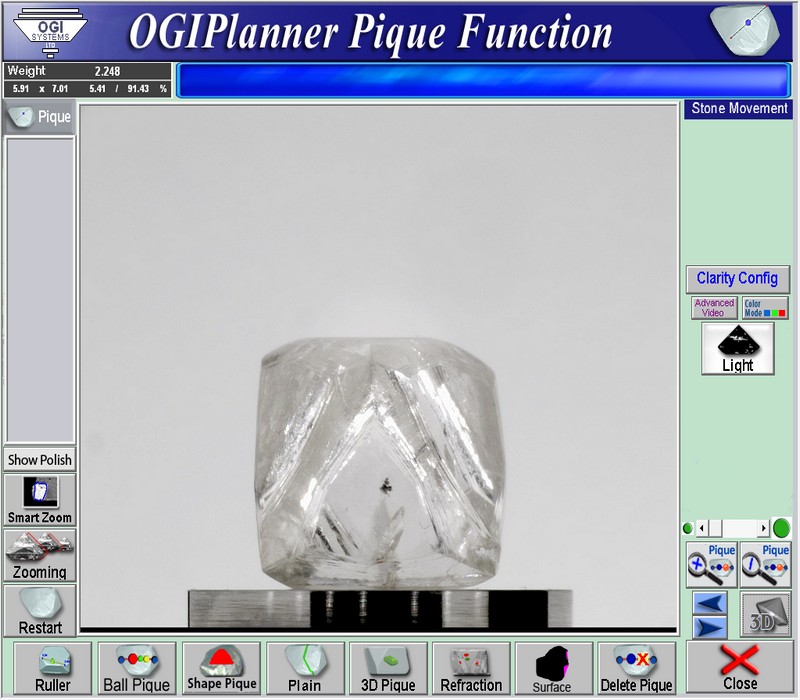

Pique Inside

|

|

Pique Inclusion

|

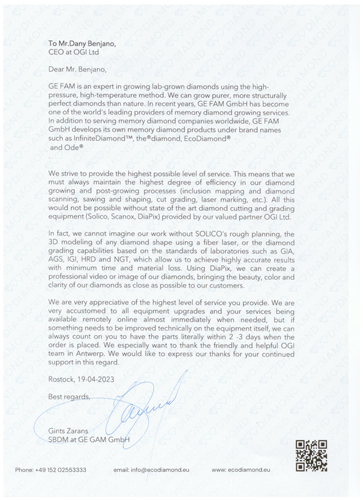

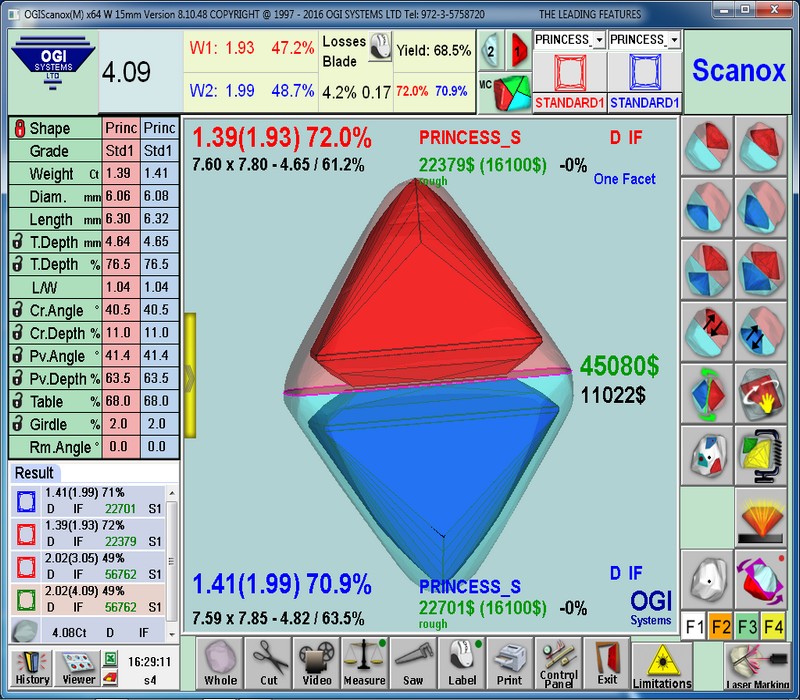

Princess

|

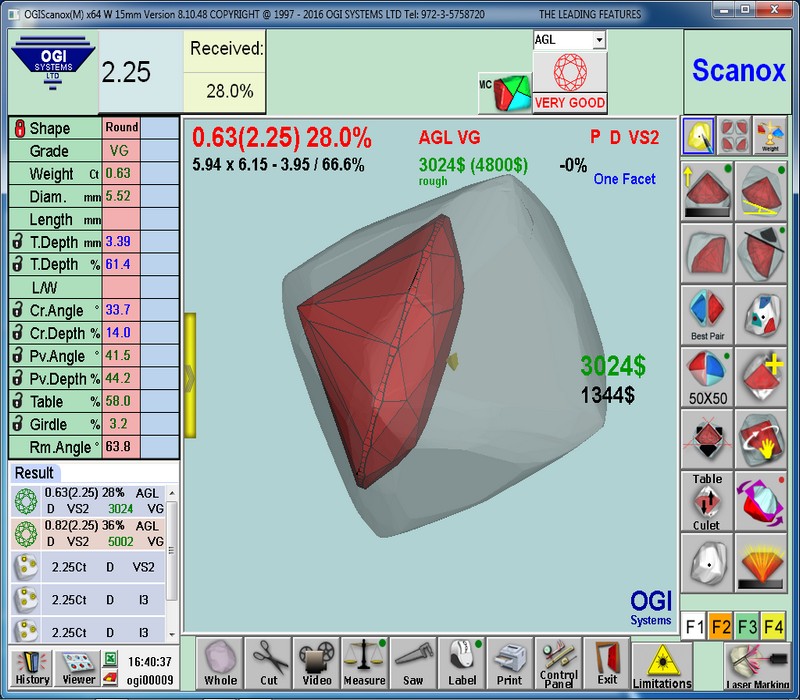

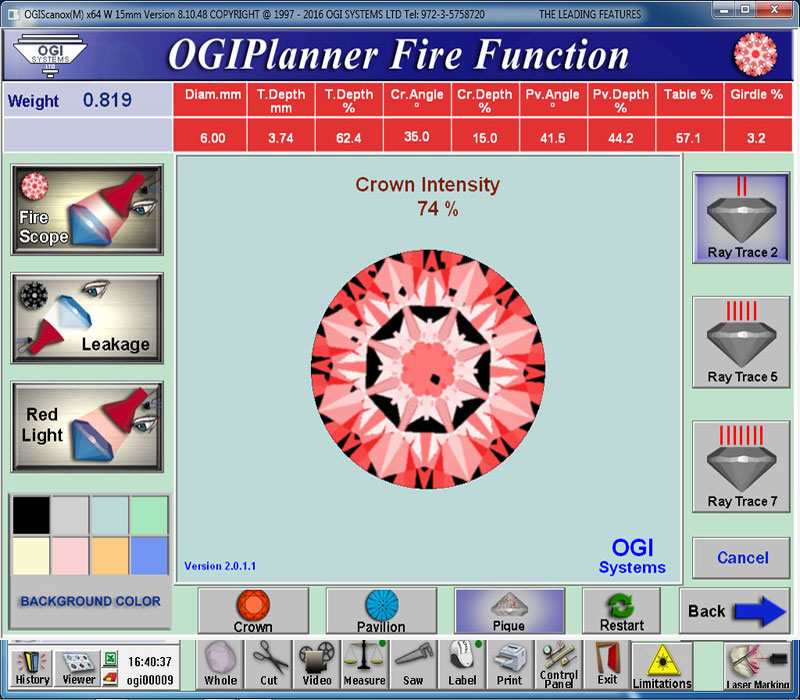

Fire Results

|

Split two twins stones

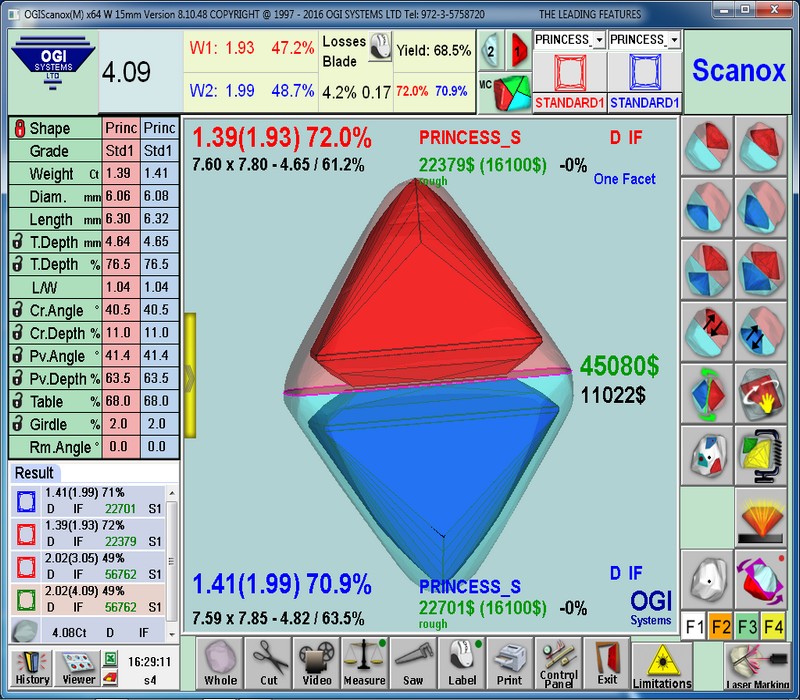

The best result without inclusion

Inclusion effect simulate on polish stone

Plotting glez simulate on rough stone

Plotting whole simulate on rough stone

Analyze multiple shape and gives the best value

Maximize polished pcs in one stone with different shape

Optimize multi pieces to get maximum use

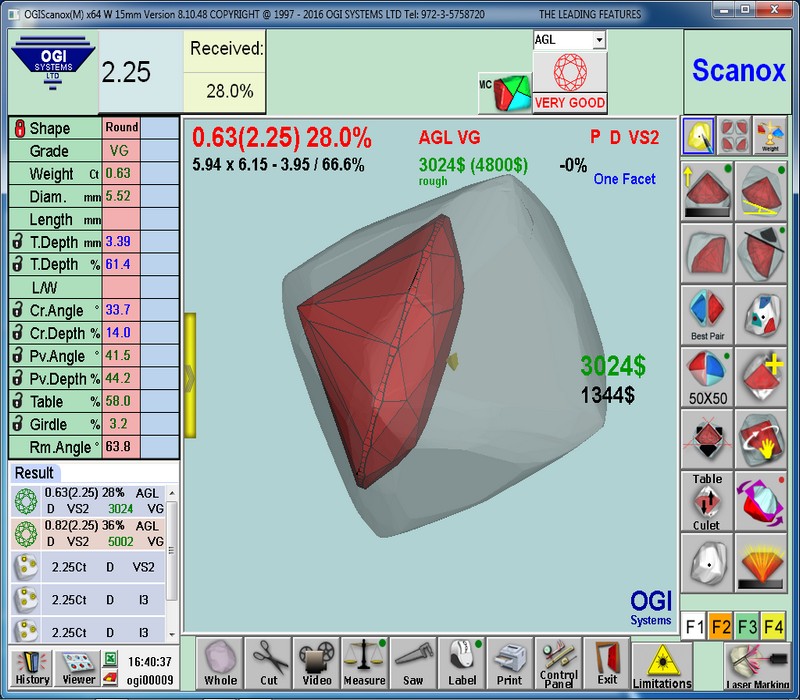

Analyze the best weight with inclusion after plotting

Inclusion reflects visible

Best planning for princess shape

Predict analyzing of the light performance

Diamonds Solution

All kind of cutting steps to get the maximum yield

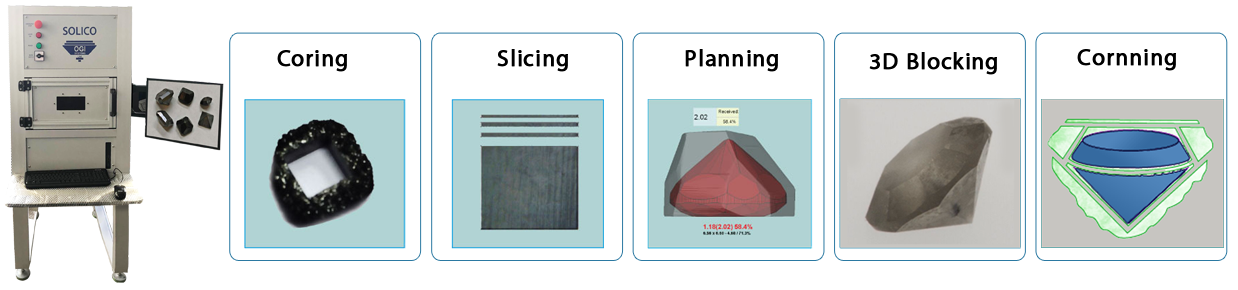

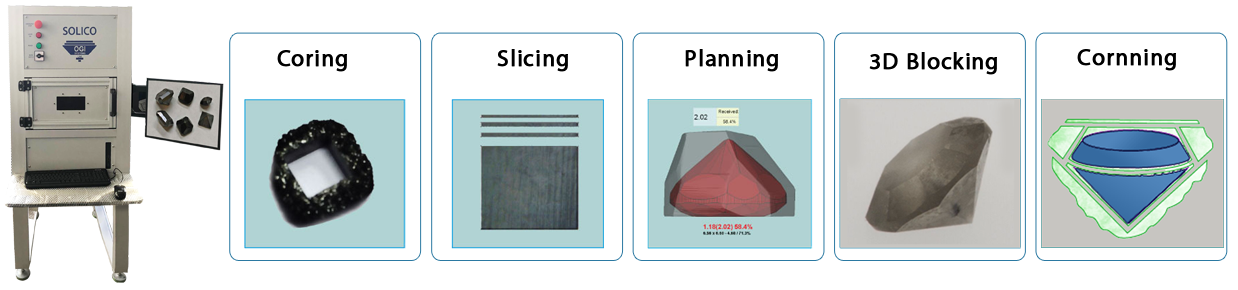

CVD Solution

All kind of cutting steps from growing to the end

Shape samples

Modern factory process

Save man power, Save other machines, Save time - MAXUMUM PROFIT

HIGHLIGHTS

- Embedded rough planning software

- Able to make only marking

- Only able to saw the diamond at the middle or saw a window that able to see the inclusions

- Able to saw any pre-determined shaping and 3D blocking

- Have option to customize any 3D facet pattern (separate cost)

- For CVD lab grown diamond, it has special software to remove coring or slicing or blocking in 3D of any shape

TECHNICAL SPEC

- WEIGHT

- VOLTAGE

- Dimensions

- Laser Type

- Cooling

- Cutting time

- : 150kg

- : 220ac, 1-phase,50/60Hz,16A

- : W:160xL:66xH:130mm

- : IR Fiber laser

- : AIR pump

- : 1 hour to get 1 carat round blocking

Diamond Factory installed

ONE YEAR WARRANTY