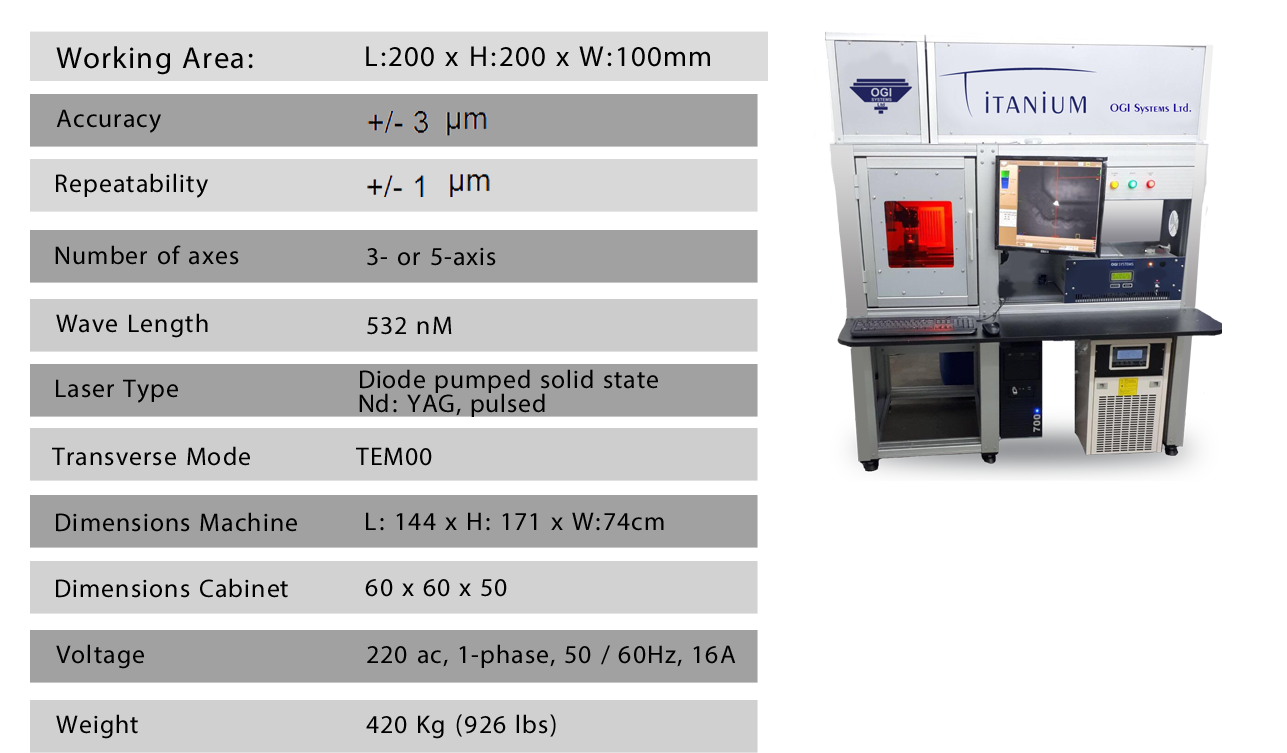

TITANIUM 5 AXIS

Laser Solutions for CVD & Ultra-Hard Materials

With Titanium easy to create any abrasives tools for honing ring, grinding wheels, Milling Cutter, Cutting inserts, Gear Cutting Tools, Chamfer & Deburring Tools, CBN Insert and more.

The Titanium Laser 5X System is a revolutionary machine that is replacing all other previous methods for cutting, eroding and grinding by using powerful green lasers.

It is an accurate machine capable of cutting ultra-hard material through a gentle method and guarantees remarkable surface quality.

High quality laser beam enables high cutting speed and accuracy, law kerf width and straight profile.

Supports the import of 2D shapes from CAD (Computer-Aided Design).

Safe laser and processing doors are equipped with safety locks.

User friendly, easy to manipulation of X-Y stage and Z (focus) axis.

Built in Cooling System and vacuum cleaner.

Rugged construction: laser, optics and tables are mounted on a Stabilized steel frame.

Sawing is done in mass production, 24/7.

Optional 5 Axis model.

Use of ultra-hard materials is growing in various industries and many manufacturers face the challenging need to increase their capability of manufacturing and cutting of these materials.

The Titanium is a multi-faceted laser cutting machine that is capable of cutting

PCD, CBN, PCB and PCBN used for Abrasive Tools, cutting tools, chip breakers,

tipped inserts, milling inserts, micro endmil, and more. This system offers

ideal angles and cutting edges without any chips or breaks.

It produces excellent surface finishes and offers separating or 'cutting out' of

PCD and CBN cutting inserts. Titanium allows users to easily plan and execute

unlimited geometric options and accurate lines for chip breakers.

The Titanium Laser System is the machine of choice for the manufacturing of medical devices such as diamond knives and blades .

This system is adaptable to complex geometric shapes that are needed for medical devices and their parts. The Titanium guarantees smooth surfaces and accurate corners. It generates high-quality outcomes with no thermal damage.

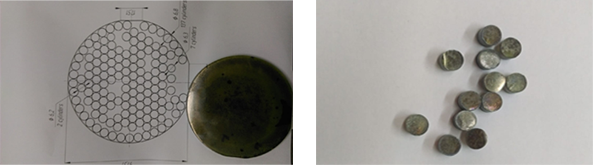

Lab-grown diamonds are generally produced with chemical vapor deposition (CVD) or high pressure high temperature (HPHT) method material for industrial applications.

The titanium laser assists in optimizing the production from each single-crystal diamond.

Titanium laser-cutting produces perfect coring and slicing from every

diamond seed.

Cutting perfectly smooth substrate for the production of seeds used to increase

returns of CVD

The Titanium is exceptional because of its altering parameters to provide optimal size range, thickness and shape for cutting CVD diamond film.

This film is the ultimate semiconductor thermal management solution that guarantees highest efficiency using the lowest possible temperatures.

Cutting perfectly smooth substrate for the production of seeds used to increase

returns of CVD

For general purpose such as slotting, side cutting and profiling.

Applications of ultra-precision diamond tool:

Cutting tool with its edge exploiting the characteristics of single crystal diamond.

Titanium makes high-accuracy grinding of the cutting edge enhances the sharpness

and durability of the edge, making the cutting tools ideal for microfabrication

with a degree of nanometer accuracy.

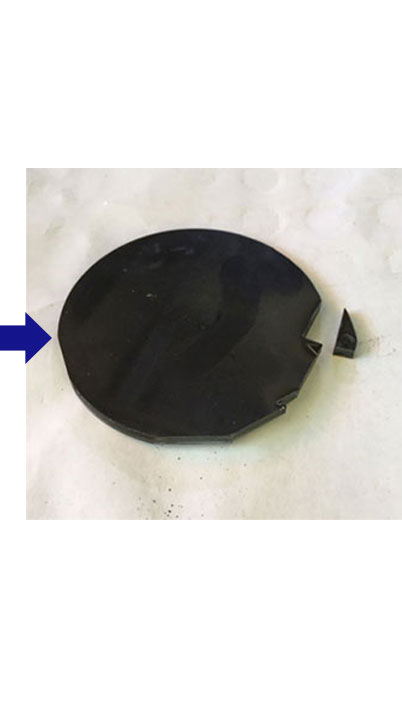

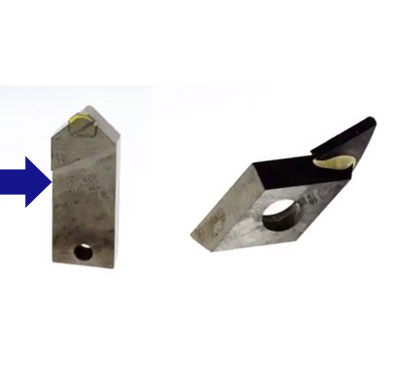

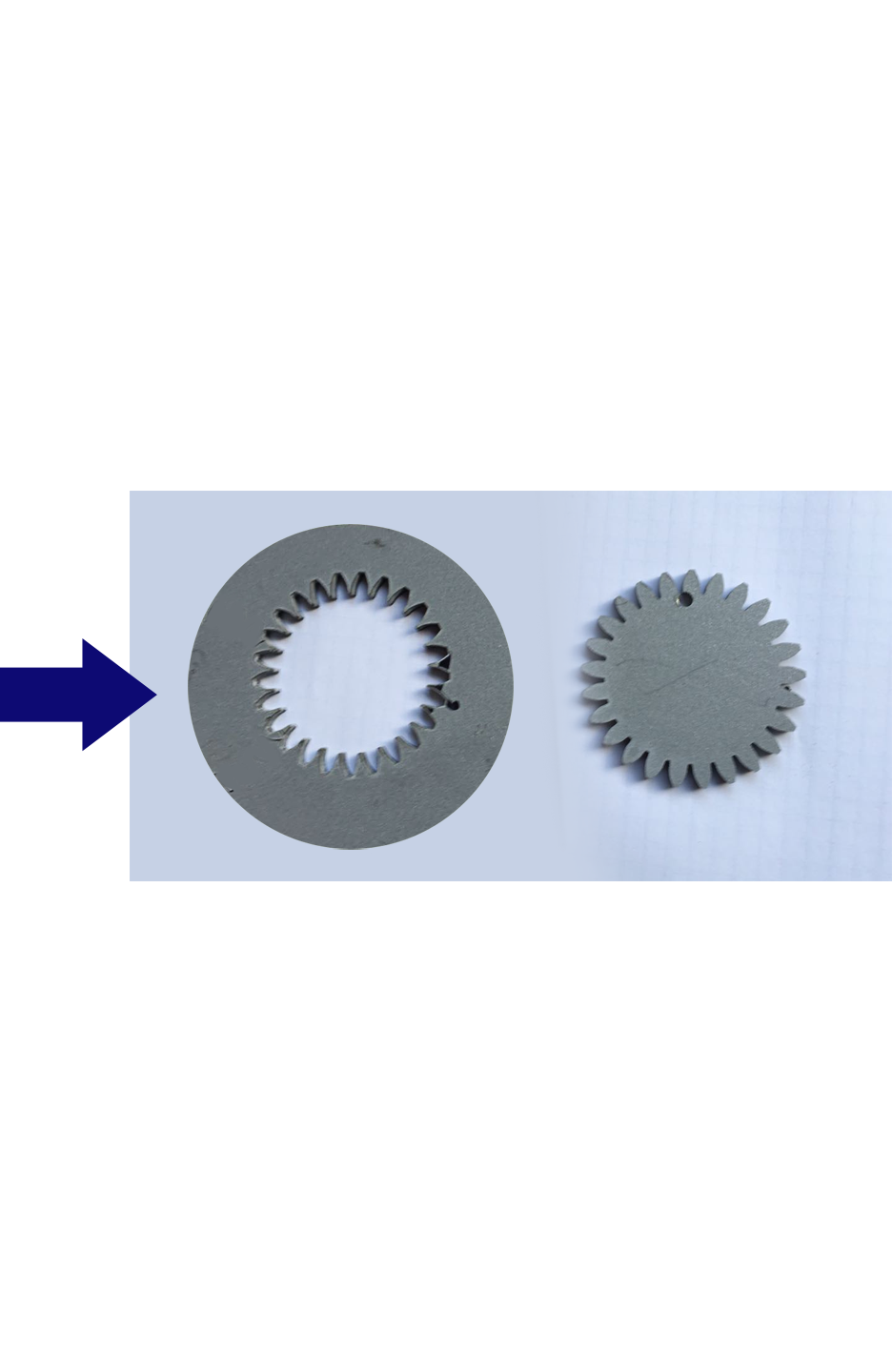

Before Titanium process

After Titanium process

|

PCD Slice |

|

|

Diamond Tools abresive |

|

|

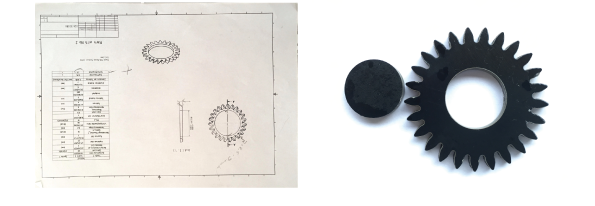

Gear shape from PCD Material |

|

Other Productions

The laser technology utilization, together with the high demand for ultra-hard materials, are opening up potential applications in a wide array of industries.

You can use our OGI Lab service center to give demo or for job work.

* 1 YEAR WARRANTY.